Key Differences in Industrial Finishing

Liquid painting and powder coating are two popular methods used in industrial finishing, each offering distinct advantages depending on the application. Both typically require a heat-curing process but differ in their techniques and final results. While liquid painting has been the traditional go-to method, powder coating has gained popularity due to advances in technology, offering a durable and eco-friendly alternative for various substrates.

Process

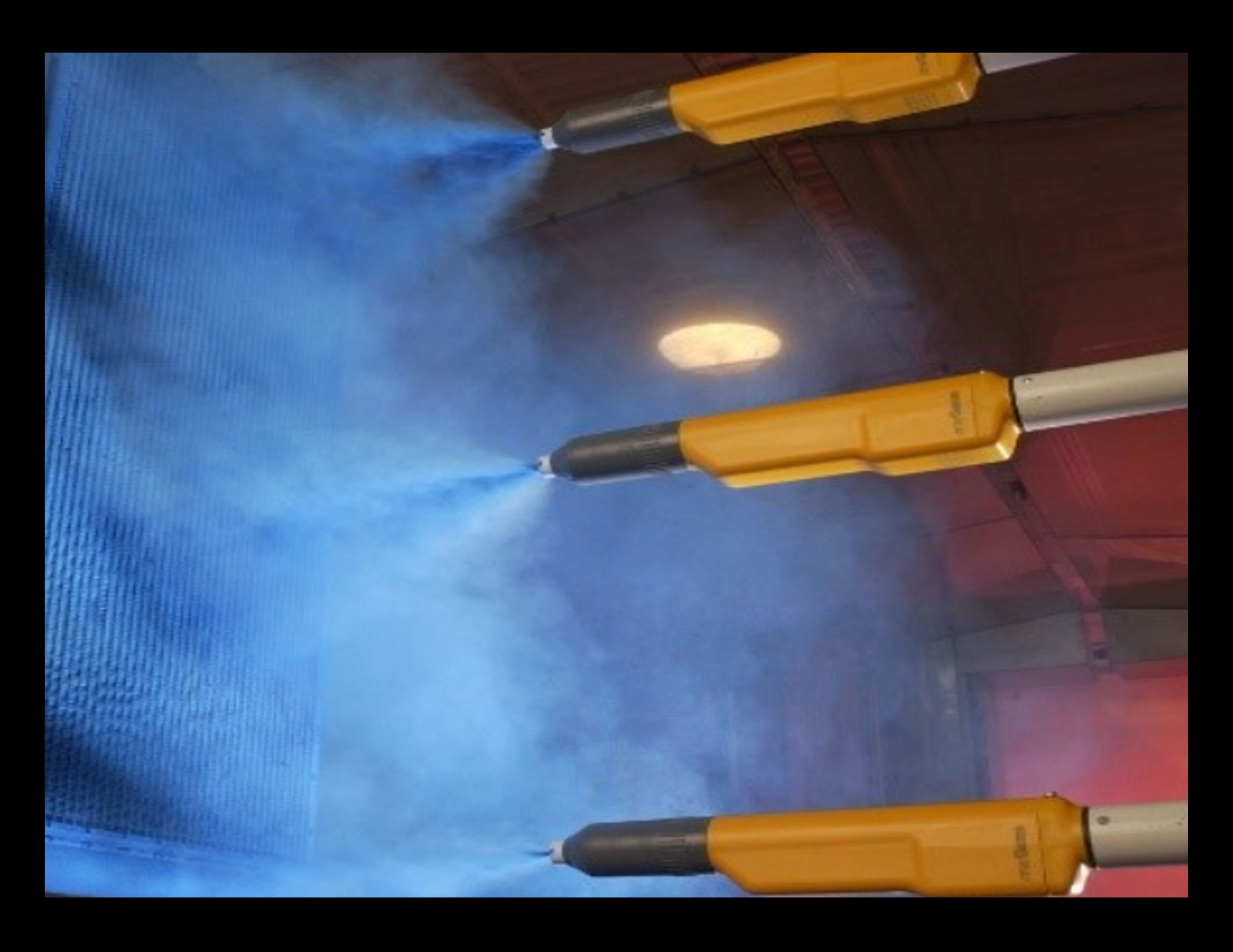

Liquid painting involves applying a layer of liquid paint to a surface, usually with a spray gun or brush. The paint dries through exposure to air or UV light, creating a protective and decorative coating. It’s a straightforward process suitable for many materials and finishes.

Powder coating, on the other hand, uses a fine, dry powder that is electrostatically charged and sprayed onto the surface. The coated item is then baked at high temperatures, causing the powder to melt and form a uniform, solid layer. This method results in a thicker, more durable finish than traditional paint.

Durability

One of the key differences between the two is durability. Liquid paint creates a smooth, glossy finish, but it is more prone to chipping, peeling, and fading. Over time, this can expose the underlying surface to rust and corrosion, especially in harsh environments.

Powder coating offers superior protection against damage. Its seamless surface resists chips, scratches, and fading, making it ideal for products exposed to the elements or heavy use. In fact, powder-coated finishes can last up to 20 years, providing long-lasting durability at a lower cost than liquid paint.

Curing

Curing is a critical part of both processes. Liquid paints cure as solvents evaporate, leaving behind a hardened layer. High-temperature curing typically takes 15 to 20 minutes at around 170 to 180°C (338 to 356°F). Some liquid paints contain catalysts that allow them to cure at room temperature or with moisture, but the overall process can be slower and less efficient.

Powder coating, by contrast, cures faster, usually at 200°C (392°F) for 10 to 15 minutes. The powder melts and flows over the surface to form an even, durable layer. This rapid curing process makes powder coating an excellent choice for high-volume production.

Environmental Impact

One of the biggest benefits of powder coating is its environmentally friendly nature. Unlike liquid paints, which release volatile organic compounds (VOCs) into the atmosphere, powder coatings contain no solvents and emit no harmful chemicals. Additionally, excess powder can be recycled and reused, reducing waste and ensuring nearly 100% material efficiency.

In contrast, liquid paints are less eco-friendly due to their VOC emissions, which contribute to air pollution and pose health risks. Liquid paint waste also requires special handling and disposal, making it less sustainable in the long term.

Usage

Liquid paint is ideal for applications requiring a thinner, more precise coating, particularly for items with tight tolerances. It’s also commonly used for smaller production runs or on materials like plastic, which can’t tolerate the high heat needed for powder coating. Liquid paint offers more flexibility with specialized finishes such as high-gloss or metallic colors, which can be challenging to replicate with powder coatings.

Powder coating, on the other hand, excels in producing thicker, more protective layers. It’s the go-to option for metal products that require a highly durable finish, such as outdoor furniture, automotive parts, and industrial equipment. While it may not offer the same range of finishes as liquid paint, its toughness and longevity make it an excellent choice for high-wear items.

Conclusion

Both liquid painting and powder coating have their place in industrial finishing, but the choice between the two depends on factors like durability, environmental impact, and the specific needs of the product. For long-lasting, environmentally friendly coatings, powder coating is the clear winner. However, when precise finishes or specialized colors are required, liquid paint still holds its own as a versatile and widely used option.